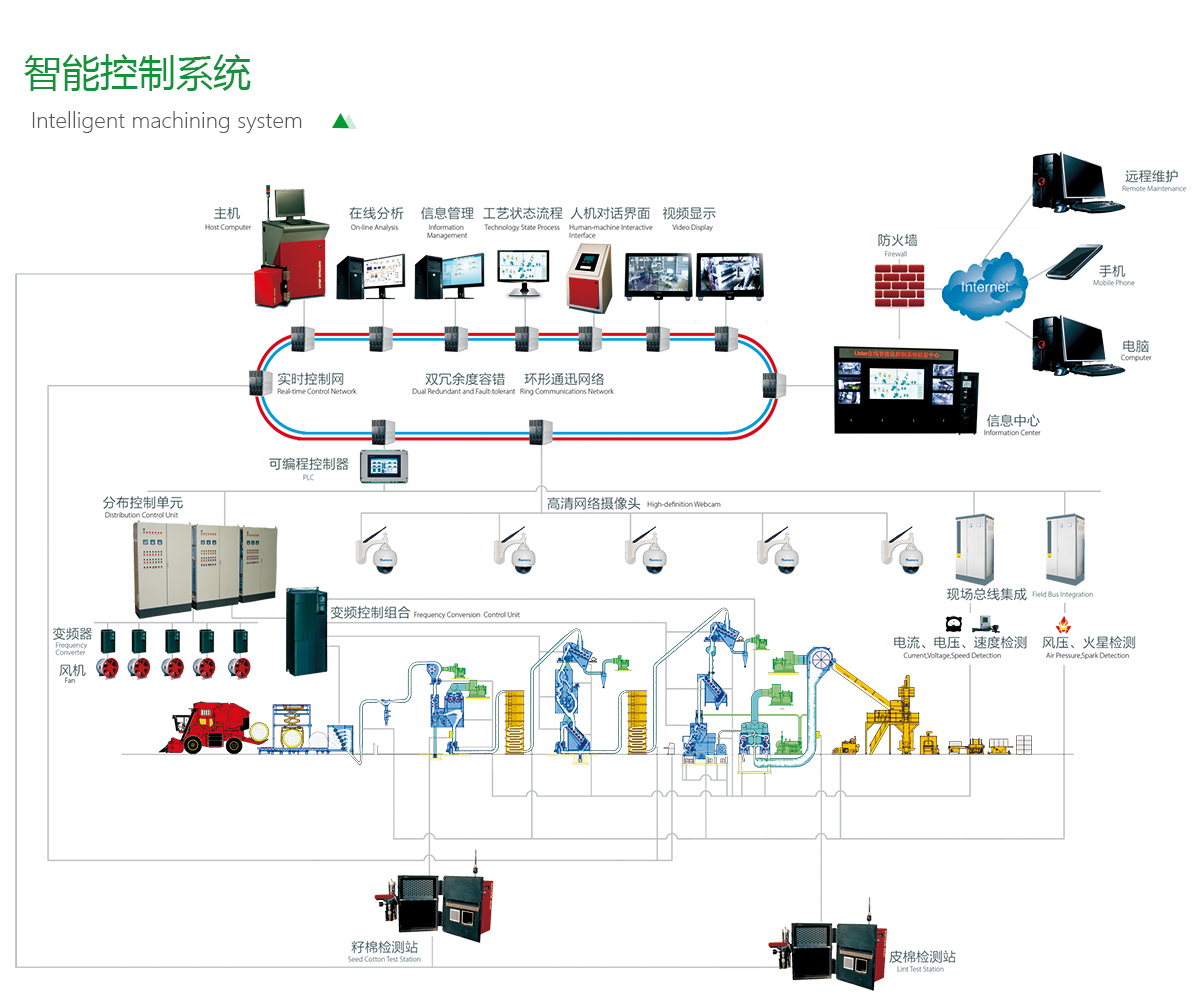

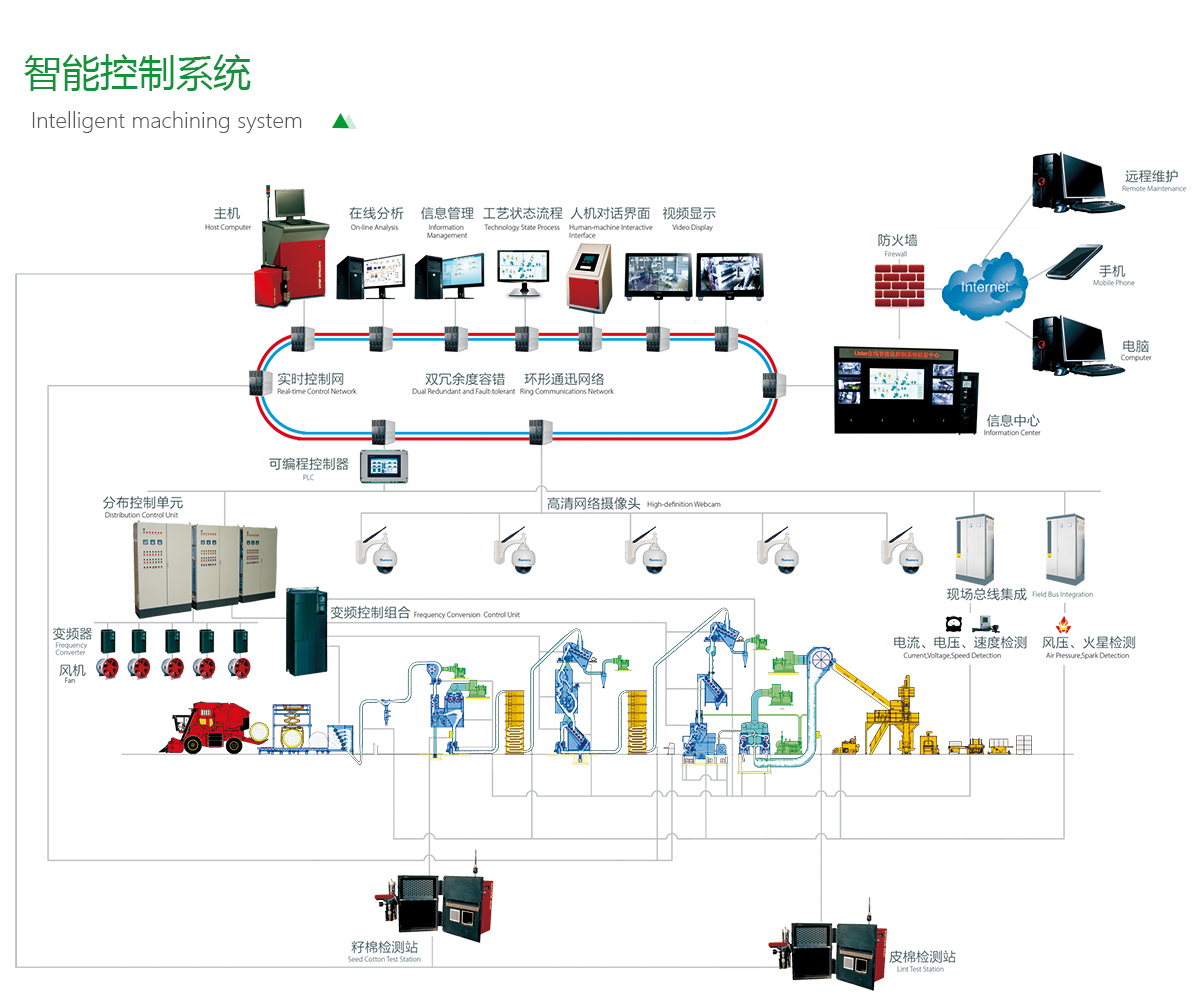

1. Online inspection system: the main quality parameters of seed cotton and lint are tested online using same technology and testing standard compatible with HVI testing equipment.

2. Intelligent analysis system: automatically compare the cotton quality information monitored online with the set target values, and provide an optimized processing scheme at any time.

3. Adjustment execution system: automatically adjust the equipment parameters and processes according to the optimized processing scheme provided by the intelligent analysis system.

4. Monitoring system: real-time collection of digital signals and video signals in the production process, and analysis and processing, in order to control the operation of equipment and adjust at any time.

5. Energy-saving system: the complete power system is automatically adjusted online, efficient and energy-saving.

6. Information management system: collect, analyze and process all kinds of information data from production line, and provide conditions for accurate accounting check of ginning factory.

7. Security system: a complete set of intelligent protection devices are equipped to ensure the safety of people and equipment, and eliminate potential safety hazards such as fire and personal injury.

8. Remote maintenance support system: provide remote technical support and services through safe and reliable communication channels.

9. Information center: timely collect relevant information from multiple production lines, convenient for resource sharing and optimal management.

Message

Message